bounty hunter tracker iv user manual

The Bounty Hunter Tracker IV is a user-friendly metal detector designed for beginners and hobbyists. It offers simplicity, ease of use, and effective performance across various conditions. With its motion-based detection and preset ground balance, it simplifies metal detecting, making it accessible for those new to the hobby. This model is ideal for finding coins, jewelry, and relics, supported by a comprehensive user manual that guides assembly, operation, and customization.

Overview of the Tracker IV Metal Detector

The Tracker IV is a user-friendly metal detector designed for simplicity and effectiveness. It features a streamlined design with minimal controls, making it ideal for beginners. With its preset ground balance, it adapts to various terrains, including beaches and shallow water. The detector includes an 8-inch waterproof search coil, enhancing versatility. It operates on 9-volt batteries and is lightweight for extended use. Its motion-based detection requires sweeping the coil to identify targets, ensuring accurate results in diverse environments.

Key Features and Benefits

The Tracker IV offers a range of features that make it an excellent choice for metal detecting. Its motion-based detection system ensures accurate target identification, while the preset ground balance eliminates manual adjustments. The detector includes an 8-inch waterproof search coil, suitable for use in shallow water and various terrains. It operates on 9-volt alkaline batteries, providing long battery life. Designed for ease of use, the Tracker IV is lightweight and ideal for both beginners and experienced users, delivering reliable performance in diverse environments.

Why Choose the Tracker IV for Metal Detecting

The Tracker IV is an excellent choice for metal detecting due to its ease of use and versatility. It is perfect for beginners and experienced users alike, offering reliable performance in diverse environments. The detector’s lightweight design, motion-based detection system, and preset ground balance make it ideal for hassle-free metal detecting. Its ability to operate in various terrains, including shallow water, adds to its appeal. Whether you’re searching for coins, jewelry, or relics, the Tracker IV provides a seamless and enjoyable experience for all skill levels.

Understanding the Tracker IV User Manual

The Tracker IV user manual is a comprehensive guide that covers the detector’s operation, features, and troubleshooting. It includes detailed instructions for assembly, customization, and optimal use, ensuring users can maximize their metal-detecting experience. Available in PDF format, the manual provides clear, step-by-step information to help beginners and experienced users alike get the most out of their Tracker IV metal detector.

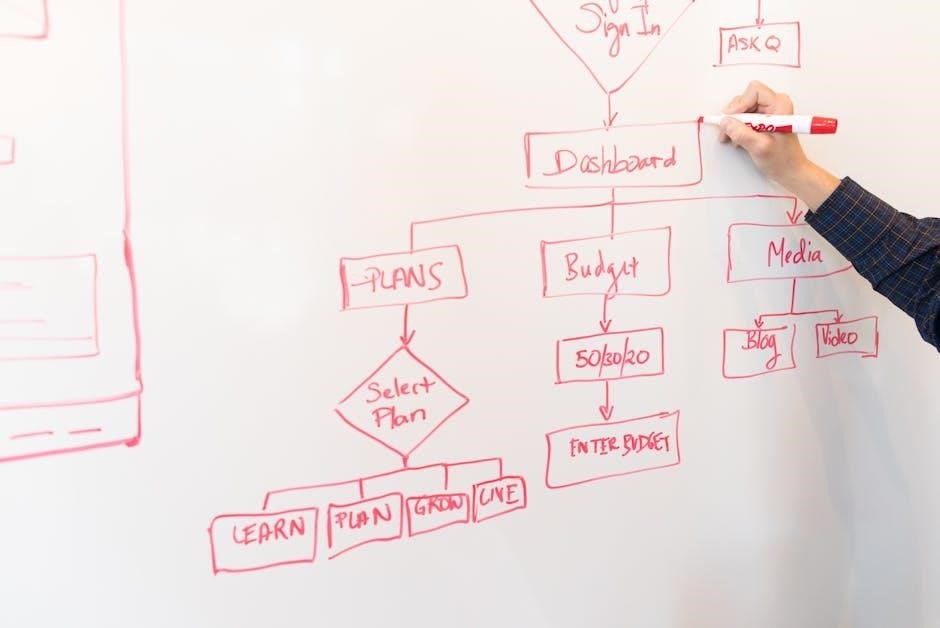

Contents of the Owner’s Manual

The Bounty Hunter Tracker IV owner’s manual provides detailed guidance on assembly, basic adjustments, and operation. It covers key features, such as motion detection, preset ground balance, and operating modes like All-Metal, Tone, and Discrimination. The manual also includes instructions for customizing settings, troubleshooting common issues, and maintaining the device. Step-by-step instructions and diagrams help users understand how to interpret signals and optimize performance in various terrains, ensuring a comprehensive understanding of the Tracker IV’s capabilities and proper usage.

Advanced Settings and Customization

The Tracker IV allows users to fine-tune their experience through advanced settings. Adjustments include sensitivity levels to enhance signal detection and discrimination controls to filter out unwanted targets. Customizing the search coil settings enables better performance in specific terrains, such as beaches or gold prospecting areas. The manual provides clear instructions on how to modify these settings to suit individual preferences and environmental conditions, ensuring optimal metal detecting results.

Downloading the PDF Manual

The Bounty Hunter Tracker IV user manual is readily available for download in PDF format from various online sources, including the official Bounty Hunter website. This comprehensive guide provides detailed information on features, operation, and troubleshooting. Users can access the manual by visiting authorized websites or platforms like ManualsLib. Ensure to download from trusted sources to avoid unauthorized modifications. The PDF manual is an essential resource for mastering the Tracker IV’s functionality and optimizing your metal detecting experience.

Getting Started with the Tracker IV

Begin by carefully unboxing and assembling the Tracker IV, following the user manual instructions. Ensure all components are securely attached and properly aligned. Power the device using 9-volt alkaline batteries and familiarize yourself with the controls before first use.

Unboxing and Initial Setup

Upon unboxing the Tracker IV, you’ll find the search coil, shaft, control box, and necessary hardware. Insert 9-volt alkaline batteries into the control box, ensuring proper installation. Attach the search coil to the shaft and tighten securely. The detector is lightweight and ergonomically designed for easy handling. Familiarize yourself with the two operating knobs and mode selection switch. No advanced technical skills are required for assembly. Follow the user manual for step-by-step guidance to ensure everything is correctly set up and ready for use.

Assembly and Basic Adjustments

The Tracker IV requires minimal assembly. Attach the search coil to the shaft and secure it tightly. Insert a 9-volt alkaline battery into the control box, ensuring proper alignment. No complex adjustments are needed, as the detector is designed for simplicity. The ergonomic design allows for easy handling. Follow the user manual for step-by-step guidance to ensure all components are correctly assembled. Once assembled, the detector is ready for basic operation, with no further adjustments required for initial use.

Powering the Device

The Bounty Hunter Tracker IV is powered by a single 9-volt alkaline battery. To power the device, insert the battery into the control box, ensuring it is properly aligned and secured. Avoid using heavy-duty or zinc-carbon batteries, as they may reduce performance. Once the battery is installed, the detector is ready for operation. Always follow the user manual guidelines for correct battery installation to ensure optimal functionality and longevity of the device. Proper power management is essential for consistent detection performance.

Operating Modes and Techniques

The Tracker IV offers All-Metal, Tone, and Discrimination modes, allowing users to adapt to different detecting scenarios. Techniques include proper sweeping methods and adjusting settings for optimal target detection. Ground balance ensures accurate results across various terrains, while motion detection enhances sensitivity. These features make the Tracker IV versatile for beginners and experienced users alike, ensuring effective metal detecting in diverse environments.

All-Metal, Tone, and Discrimination Modes

The Bounty Hunter Tracker IV features three distinct operating modes: All-Metal, Tone, and Discrimination. The All-Metal mode detects all types of metal, ideal for relic hunting or locating valuable items. The Tone mode provides audio feedback, distinguishing between targets based on signal strength. The Discrimination mode filters out unwanted objects like trash, focusing on valuable metals. These modes, combined with motion detection and ground balance, enhance accuracy and versatility, making the Tracker IV suitable for diverse detecting environments, from beaches to gold prospecting sites.

Optimizing Performance in Different Terrains

The Bounty Hunter Tracker IV excels in diverse terrains, including beaches and gold prospecting sites. Its 8-inch waterproof search coil allows detection in shallow water, while the preset ground balance ensures stability in extreme conditions, such as saltwater or black sand. For optimal results, adjust sweep techniques based on terrain: slower sweeps for highly mineralized ground and faster sweeps for cleaner areas. The Tracker IV’s motion detection feature enhances target accuracy, making it versatile for all environments, from sandy beaches to rocky fields.

Using the Motion Detection Feature

The Bounty Hunter Tracker IV operates as a motion detector, requiring the search coil to be swept side-to-side to detect metal. A stationary coil over a target will not trigger a response. This feature enhances accuracy by reducing false signals. To use it effectively, maintain a steady, consistent sweeping motion. Adjust your sweep speed based on terrain: slower for mineral-rich soil, faster for cleaner areas. The motion detection system ensures reliable target identification, making it ideal for beginners and experienced users alike.

Advanced Features and Settings

The Bounty Hunter Tracker IV offers ground balance, sensitivity adjustments, and customizable search coil settings. These features allow users to optimize performance for various terrains and conditions, enhancing detection accuracy and versatility.

Ground Balance and Its Importance

Ground balance is a critical feature of the Bounty Hunter Tracker IV, enabling the detector to perform effectively in diverse terrains. It minimizes interference from mineral-rich soil, including salt and black sand, ensuring accurate target detection. The Tracker IV features a preset ground balance, eliminating the need for manual adjustments, which simplifies operation for users. This setting is particularly beneficial for beginners, as it allows them to focus on detecting without complex tuning. Ground balance enhances sensitivity and reduces false signals, making it essential for successful metal detecting in challenging environments.

Adjusting Sensitivity and Discrimination

Adjusting sensitivity and discrimination on the Bounty Hunter Tracker IV is straightforward, allowing users to optimize performance. The sensitivity knob controls the detector’s depth and signal strength, while discrimination helps distinguish between different metal types. Turning the sensitivity knob clockwise increases detection depth but may cause interference in mineral-rich soil. The discrimination feature filters out unwanted metals, reducing false signals. Properly balancing these settings enhances target accuracy and improves hunting efficiency in various terrains.

Customizing Search Coil Settings

The Bounty Hunter Tracker IV allows users to customize search coil settings for improved detection. The standard 8-inch waterproof coil is versatile for various terrains, including shallow water. Users can adjust the coil height and angle for optimal performance. Additionally, optional coil upgrades enable tailored detection for specific needs, such as larger coils for deeper searches or smaller coils for precision. Customizing these settings enhances target detection and adapts the detector to different hunting environments effectively.

Tips for Effective Metal Detecting

For effective metal detecting, maintain a steady sweep, adjust sensitivity, and use appropriate coils for terrain. Practice technique to enhance target detection accuracy and efficiency.

Choosing the Right Search Coil

For optimal performance, select the right search coil based on terrain and targets. The Bounty Hunter Tracker IV comes with an 8-inch waterproof coil, ideal for shallow water and general use. Smaller coils are better for targeting small objects in tight spaces, while larger coils cover more ground and detect deeper targets. Always match coil size to hunting conditions for improved sensitivity and accuracy. Regularly clean and inspect coils to ensure proper functionality and maintain detection efficiency.

Best Practices for Sweep Techniques

For effective metal detecting with the Bounty Hunter Tracker IV, maintain a steady, side-to-side sweeping motion. Keep the search coil close to the ground to maximize detection depth. Avoid rapid or erratic movements, as consistent speed ensures accurate target identification. Overlap sweeps slightly to cover the area thoroughly. On uneven terrain, adjust your technique to keep the coil stable and avoid false signals. Practice sweeping evenly to enhance detection accuracy and improve your overall metal detecting experience.

Interpreting Signals and Targets

Understanding the signals and target responses on the Bounty Hunter Tracker IV is key to successful metal detecting. The detector provides clear audio and visual feedback, with tone changes indicating different metal types. Steady, consistent signals often point to larger or deeper targets, while erratic signals may indicate smaller objects or trash. Practice interpreting these cues to distinguish between valuable finds and unwanted items. Accurate interpretation enhances efficiency and ensures you uncover hidden treasures effectively.

Troubleshooting and Maintenance

Refer to the Bounty Hunter Tracker IV manual for common issues like battery life, sensitivity adjustments, and coil damage. Regular maintenance ensures optimal performance and longevity.

Common Issues and Solutions

Common issues with the Bounty Hunter Tracker IV include low battery life, inconsistent sensitivity, and coil damage. Solutions involve replacing 9-volt alkaline batteries, adjusting sensitivity settings, and ensuring proper coil maintenance. Avoid using heavy-duty or zinc-carbon batteries, as they may reduce performance. Regularly clean the search coil and store it properly to prevent damage. Refer to the user manual for detailed troubleshooting steps and maintenance tips to ensure optimal functionality and extend the detector’s lifespan.

Regular Maintenance Tips

Regular maintenance ensures the Bounty Hunter Tracker IV performs optimally. Clean the search coil after each use to remove dirt and debris. Inspect cables for damage and ensure secure connections. Store the detector in a dry, cool place to prevent moisture damage. Replace the 9-volt alkaline batteries when power depletes. Avoid using heavy-duty or zinc-carbon batteries, as they may reduce performance. Follow these tips to maintain your Tracker IV’s reliability and extend its lifespan for consistent metal detecting experiences.

Updating Firmware and Software

Periodically check the manufacturer’s website for firmware and software updates for the Bounty Hunter Tracker IV. Download the latest version using a computer and follow the installation instructions carefully. Ensure the detector is fully powered during updates to avoid interruptions. After updating, restart the device to apply changes. Keeping your Tracker IV updated ensures optimal performance, new features, and compatibility with the latest enhancements. Always follow the user manual’s guidance for a smooth update process to maintain your metal detector’s functionality and efficiency.